About Us

Ever since its inception in the year 2018, we have completed countless ventures to provide the service. We are the first service provider for Turbo Air Ventilators. Our service team is well equipped to provide the perfect service for industrial TURBO AIR VENTILATOR roof top fans. The company started in July 2018. We have more than 10 service teams. A Roof Man Work is at the forefront of service provider for Turbo Air ventilators in India. In order to meet the best performance standards of Turbo Air Ventilators, we shall provide turbo air ventilator service all over India by sending our team wherever the service is required. We have a Managers, Technical Engineers, SITE Supervisor and Service Staff who are well qualified, skilled in technology with customer orientation and are strongly and efficiently guided by our CEO MS.GEETHA.M.

Our Mission

Real service, true quality is our mission. The Roofing sheds Orientated issues of industrial companies will be serviced on time and the service will be depending on the issue. Our customer support teams are available for 24X7. Our team work focuses on customer satisfaction and we have proven that we are best service provider.

Our Plan

We have a plan to work smart and technically. We work structurally with different teams. These great teams are support to provide the service successfully. This is designed to be gradual.

Our Vision

We are ready to reach our service tank across India. We have been providing the services in Tamil Nadu, Hyderabad, Mumbai, Kerala, Andhra Pradesh and Karnataka. Therefore, we are well versed to provide proper service to Turbo Air Ventilator and Roofing Sheet Orient issues all over India.

Services

We have solutions for this all complaints with updated materials and equipments. And more we are giving Warranties for this all services.

TurboAair Ventilator Top Doom Damages Service,

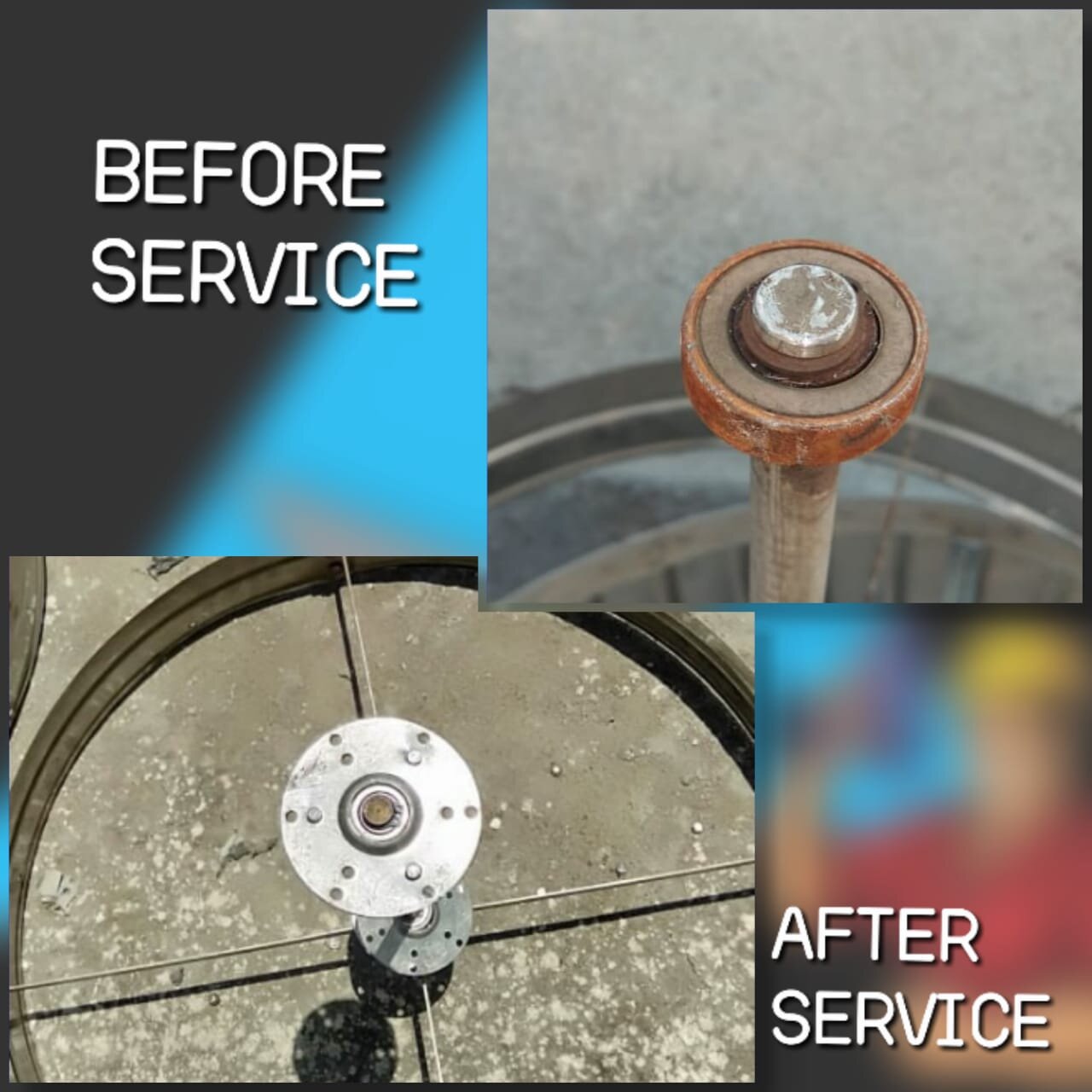

The TURBO AIR VENTILATOR top doom Bearing cap damage, these issues will arise because of moulded bearing cracked and due to this bearing will come out from mould. The TURBO AIR VENTILATOR bottom Chassis Ring bearing will rotate in wind and because of this action the top bearing hit on doom cap. The rust on soft rode can damage TURBO AIR VENTILATOR bearing system and this will stagnant on rode so that TURBO AIR VENTILATOR will not rotate.

Turbo Air Ventilator Bearing Systems Damage Service

When the TURBO AIR VENTILATOR centre soft rode get rusted, bearing will stuck and mould will become insolvent. Due to this TURBO AIR VENTILATOR might fall down and damages will occur. In case of TURBO AIR VENTILATOR bottom base plate screw condition is good, then TURBO AIR VENTILATOR chassis ring hold on the top doom. The TURBO AIR VENTILATOR bottom Chassis ring Bearing will get easily detriment because of Chemical industries, heat Burner Industries, Flame Industries, basically heat producing industries. This kind of industries TURBO AIR VENTILATOR bottom bearing will get quickly damage and due to this solid rivet will get cracked.

As TURBO AIR VENTILATOR top Bearing will get damage because of TURBO AIR VENTILATOR Bottom bearing damage or broken and this quickly damages top bearing and due to this solid mould will get crack. The Plastic moulded inner ring guard will broke because of expiry time. This is the main ring to lock the bearing if it is broken then bearing will came out.

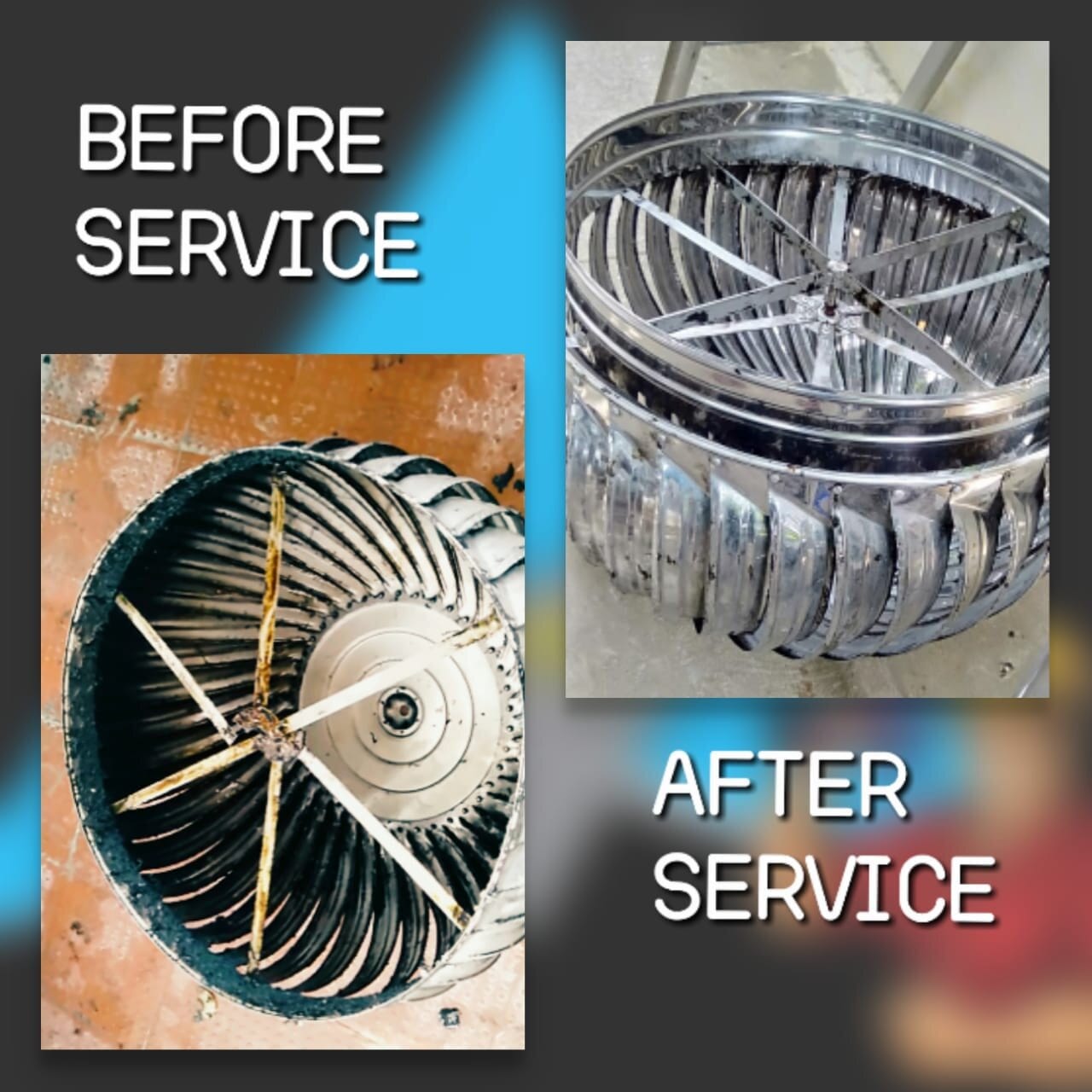

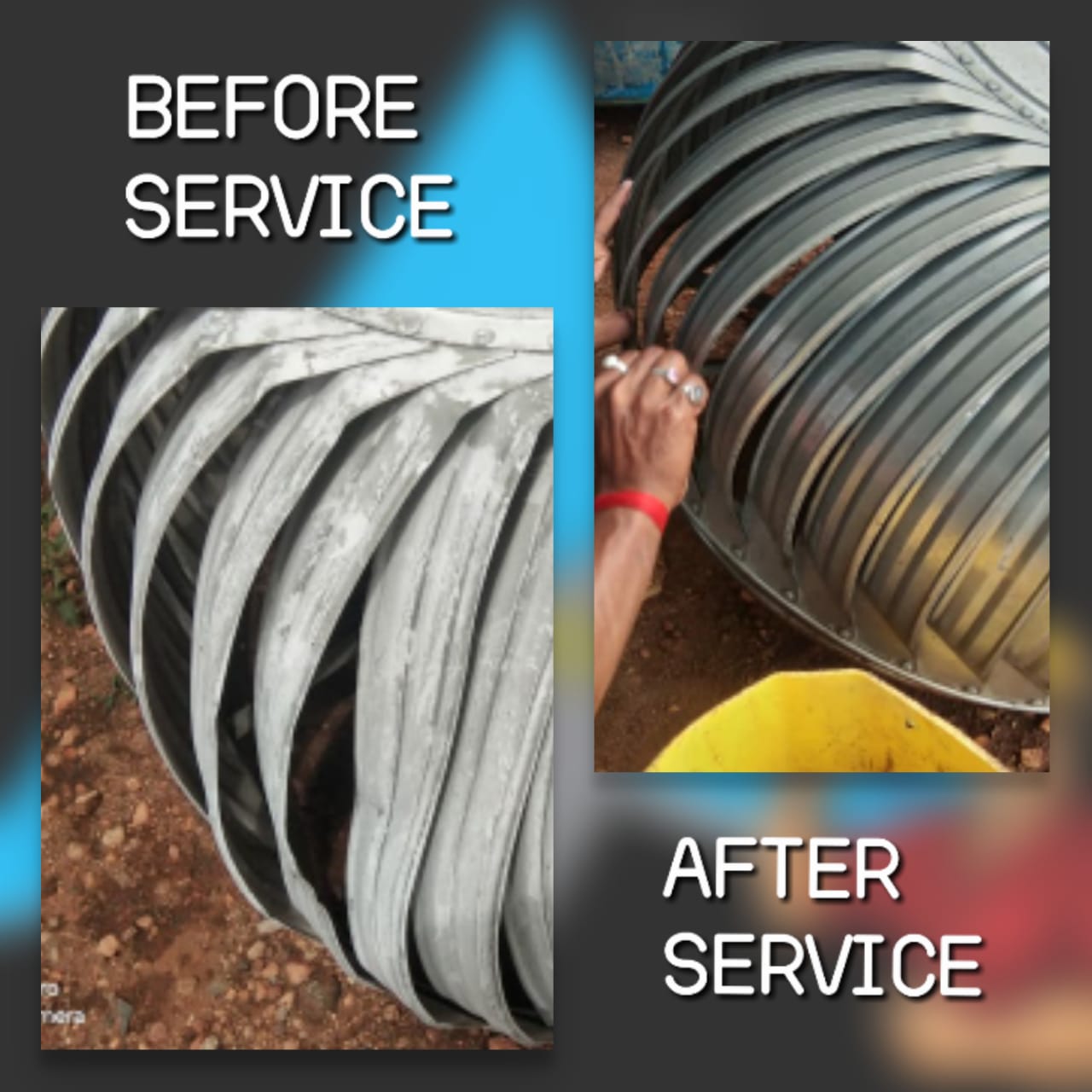

Turbo Air Ventilator Blades Damage Service

The TURBO AIR VENTILATOR body is made of weightless Aluminium components if any kind of particles will hit the TURBO AIR VENTILATOR blades this cause the damage easily. We will grooves on TURBO AIR VENTILATOR Blade it will protect in Heavy wind pressure and it supports to rotate the TURBO AIR VENTILATOR, but in the heavy wind there is a possibility of objects fly near to TURBO AIR VENTILATOR or hit directly to TURBO AIR VENTILATOR blades.

So TURBO AIR VENTILATOR blades are damage then this will not gave effective results and for this damage not only the objects are the reasons but there some other reason as well that is industries which produce heat, chemical smoke or dust. These industries TURBO AIR VENTILATOR blades get easily damage.

Extreme Damaged Turbo Air Ventilator Service

Any kind of extremely scraped TURBO AIR VENTILATOR can be access to run good condition. The above showed in picture the turbine is fully damaged because of no maintenance for a long time.

Turbo Air Ventilator Bottom Base Leakage and Lining Service

The TURBO AIR VENTILATOR bottom base damage happens because of life span of the product. Normaly Fiber life will be arround 3-4years and most of the heat producing or chemical industries will be within 2years. If the fiber mate come out from its layers and high chances of water leakage. The top cone of the bottom base is not tempered then TURBO AIR VENTILATOR chassis ring screw will be loosen. Due to this the TURBO AIR VENTILATORS will fall down or some times crack will come on the bottom base. There will be a vibration in metal sheet because of heavy wind. The damage on the fiber base plate of mate top layer removal happens due to atmospere and dust. We will provide the full solution for the above mentioned complaints.

Turbo Air Ventilator Fixing and Rework Service

Our company have separate installation team for TURBO AIR VENTILATOR. All kind of Roofing sheds, roofing sheet, louvers, Ridge ventilator & Ridge Gutter Installation work we do. We have proper plan to install the TURBO AIR VENTILATORS because we are specialist in turbo air ventilator installation and overall service of TURBO AIR VENTILATOR since 2010. We have manufacturing unit for TURBO AIR VENTILATOR and FRP Bottom Base Plate & Polycarbonate Bottom Base Plate. So we shall supply and install TURBO AIR VENTILATOR. We have nine years of experience to TURBO AIR VENTILATOR installation and service.

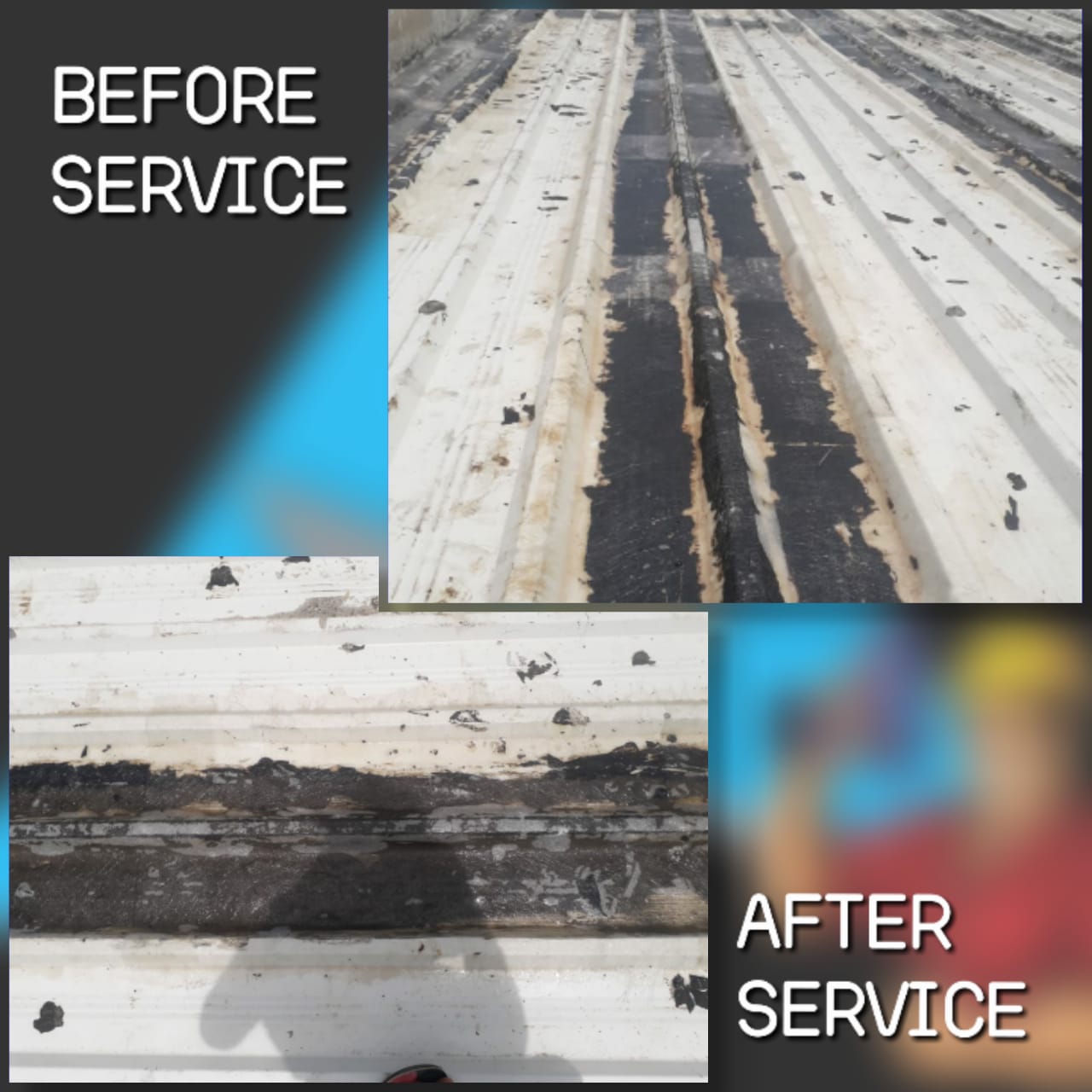

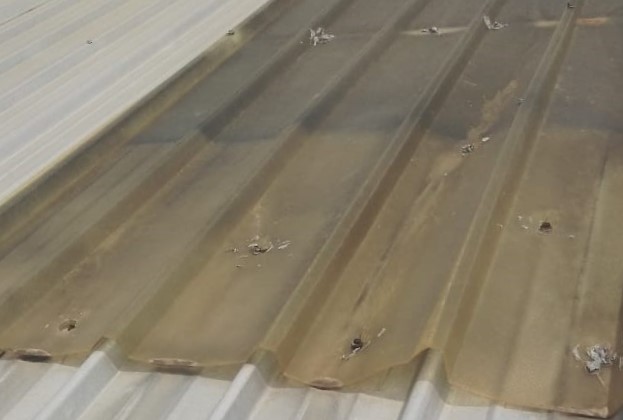

Roofing Shed Lighting Sheet Leakage Arresting Service

The lighting sheet has two type of material one is Fiber and other one is Polycarbonate, normaly Fiber sheet life will be arround 3-4years and most of the heat producing or chemical industries will be within 2years. If the fiber mate come out from its layers and high chances of water leakage. The top cone of the bottom base is not tempered then turbine chassis ring screw will be loosen. Due to this the turbines will fall down or some times crack will come on the fiber sheet. There will be a vibration in metal sheet because of heavy wind. The damage on the fiber lighting sheet of mate top layer removal happens due to atmospere and dust. Compare to Fiber and polycarbontae, the polycarbonate sheet has life span more but there are some chances of damages like lapping, screwing, vibration, heavy object and when people walk on the top. In polycarbonate sheet there are Ultra vilot coat microns (single side or both side) because of this the life span is more compared to Fiber lighting sheet. Once polycarbonate UV micron sheet compeletes the life span. Then the light transmission will not be afeective then we can analyse that there is an issue.

Roofing Sheets Water Leakage Service

In the asbestos sheet leakage happens because of crack near J Bolt, near lighting sheet, near lapping sheet or ridge sheet which was not fitted properly.

Fibre Lining and fibre Gel Coating Service

When the roofing sheets are cracked or rusted in the wall join or lapping areas this will lead to water leakage and other problem might arise that is in heavy wind the roofing sheets will fly away because of not proper lapping or rusted screws issue. If the top shed of wall has any kind of cracks we have a best solution for this.

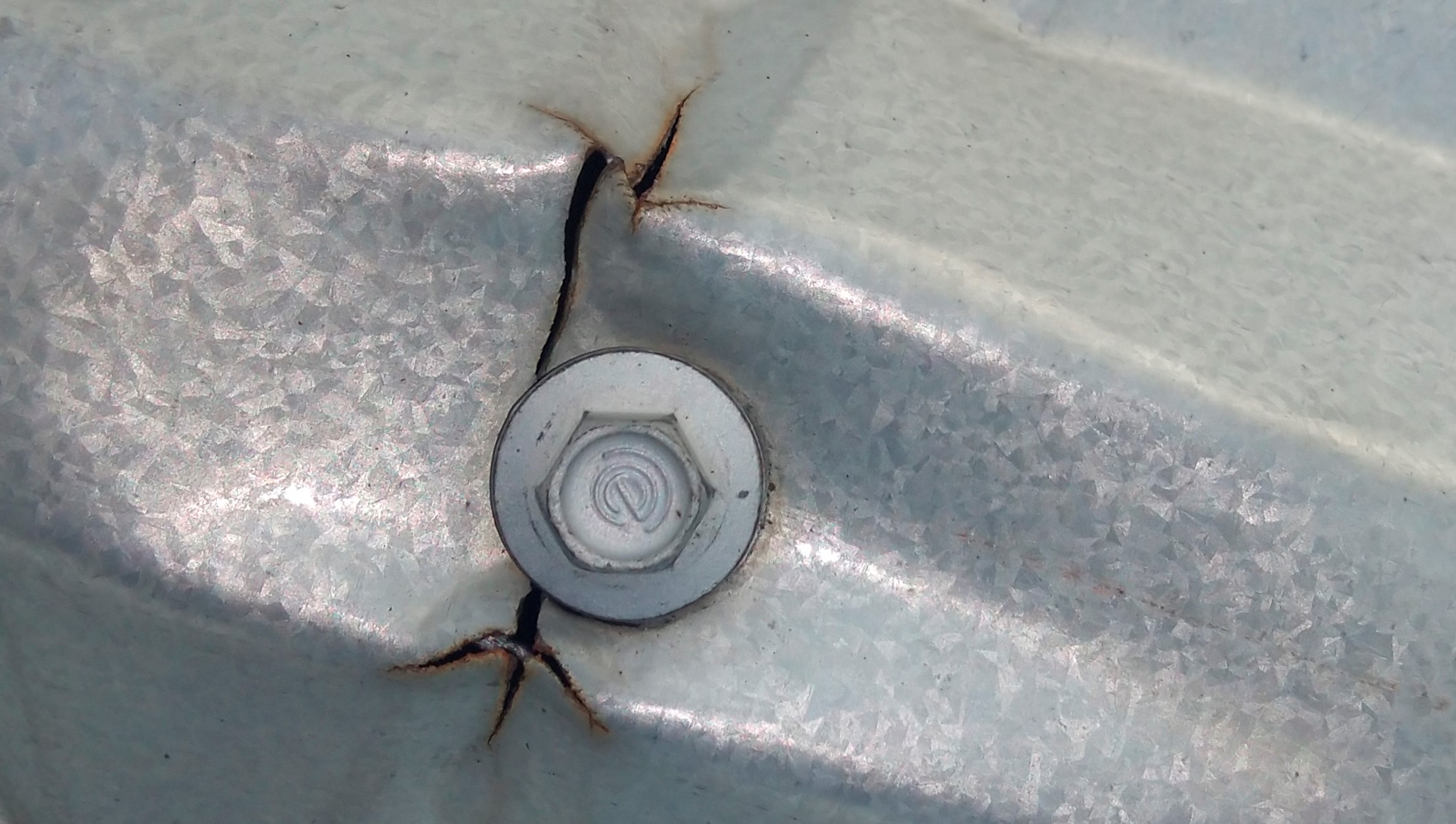

Rroofing Shed Water Leakage Patching Service

Metal roof sheet or Asbestos roof sheet will be fixed with screws or J bolt. In case of rust on Screws or J bolt, this will affect the roof sheet and screw washer will become hard and due to this washer might break into pieces. This will have gap between screw and roof sheet. Because of this gap water will leak from roof sheet. The top roof sheet will also get damaged by the objects which fly with heavy wind and this have minor crack or small hole on the roof sheet. From these small hole the leakage happens on rainy season and future the small hole will become a big hole.

From 2019 onwards we have new solution for this. Earlier we were using the silicon’s, tar sheet etc. but now we have German technology.

Ridge Ventilator Damage Service

Ridge Ventilator is a non-movable ventilator and this is placed on the centre roof top of height Shed and this also will get damages. The wind blows around 7-9kmph speed and this wind will cause the Ridge ventilator after a long period of 5-7 years as this will dislocate.

Metal louver Damages Service

This product is totally weight less. the louver was designed for dust proof. The dust accrue on the louver shelves. So after 3-4years due to dust the louver body will be heavy and this is the time that there is a chances of damage.

Call To Action

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Call To ActionComparison between before & after

Our Clients

Team

Miss. M. GEETHA

Chief Executive Officer

Mr. A. MOHANRAJ

General Manager

Mr. D. AZARUDEEN

Chief Engineer

Mr. V. RAJESH

Support Team

Mr. K. JAYASUDHAN

DeveloperContact Us

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque